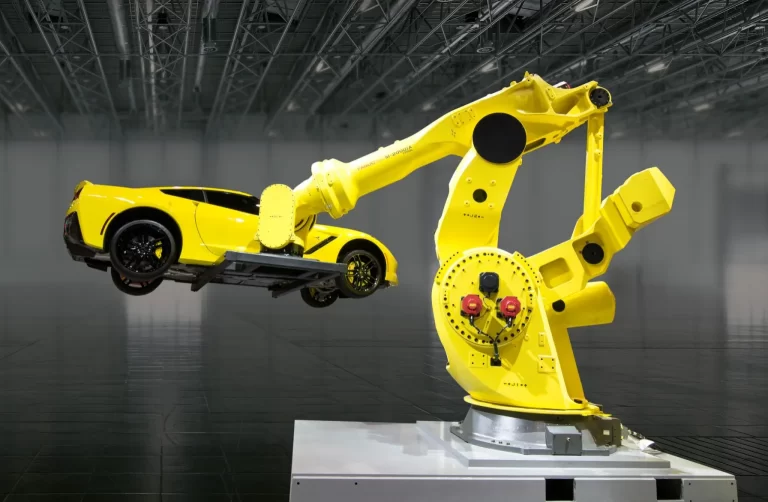

The development of robotic arms has revolutionized the manufacturing process, making use of precision, safety effectiveness, and other aspects that were previously impossible. Robot arms are technological marvels that have become indispensable in various industries throughout the world. They were developed to cut operating costs and keep high standards of quality. Robotic arms are integrating into production lines to lower cost and increase security. We’ll explore how these innovative robots are changing the face of industry.

Image credit: automatedsolutions.com.au

The cost-effectiveness of robotics is driving the adoption robots across the globe. The demands on factories to cut down manufacturing errors, material waste and workplace accidents are constant. Robotic arms are designed to tackle these problems. Robots are more precise than human beings when performing repetitive tasks, cutting down on waste and eliminating costly errors. For instance, in large-scale industries such as automotive manufacturing, robot arms execute precise welding and part positioning, ensuring flawless assembly each time. This accuracy can result in significant savings because less damaged items mean less work or waste.

Safety is the second main element to the advancement of robot arms. Human workers are in danger in the course of performing a variety of manufacturing tasks, like dealing with dangerous materials or operating heavy machinery. By using robot arms businesses can eliminate employees from these dangerous environments, drastically decreasing the chance of workplace injuries. Robotic arms, which are made up of joints which move could mimic the function of human arms and not cause physical injury. These machines are equipped with robotic hands, or programmable end-effectors. They are capable of performing tasks such as grasping, spinning and welding, in conditions that could make it unsafe for humans.

The versatility of robotic arms makes them a game-changer across diverse industries. From automotive assembly to electronics production, robotic arms are able to adapt to a wide range of jobs. Their programmable nature allows them to execute complex tasks, such as tending to a machine paint, or fiberglass application with unmatched reliability. Robotic arms have revolutionized the palletizing process in warehouses, making it easier to do with speed and accuracy. Automation does not just increase efficiency, but also reliability as robot arms are able to be productive without fatigue.

The growth of cobots (collaborative robots) that collaborate with human workers is one of the most thrilling innovations in the field. Unlike traditional industrial robots confined to isolated cells. Cobots fitted with robotic arms are designed to ensure safe and seamless interactions with humans. In a factory environment the robot arm of a cobot may be capable of handling difficult lifting or tasks that are repetitive, freeing humans to concentrate on more difficult tasks. The robots can cease or alter their motion if they detect a worker near.

The effects of robotic arms go far beyond safety and efficacy to the very foundations of modern manufacturing. The capability of robotic arms to perform tasks that require precision, such as welding, material handling, or assembly, has made them indispensable in areas where safety is the top priority. For instance, in the automotive manufacturing, a robotic arm can move and rotate parts during assembly, which ensures perfect alignment without human intervention. In the electronics industry, robots can be used to handle delicate components, which decreases damage and increases the quality of output.

As industries continue to develop as they continue to evolve, the significance of robotic arms will only increase. They can cut cost, enhance safety and be able to adapt to different tasks robotic arms will be the foundations of future manufacturing. By combining cutting-edge technology with human creativity, robotic arms are more than just instruments. They are partners that drive innovations, changing the way we construct our world.